Solar Panel technology has been commercialized for over 60 years now since the first satellite powered by solar cells went to space in 1958. Thanks to recent advancements in physics, materials engineering, industrial technology and the implementation of global supply chains driving economies of scale, Solar panels has now become a major player in the renewable energy sector driving the energy transition.

Solar modules (also referred to as ‘panels’ or ‘collectors’) constitute the most important part of a Solar system. When sunlight (or ‘photons’) hits a Solar module, it leads to the Photovoltaic (‘PV’) effect which is the generation of voltage and electric current.

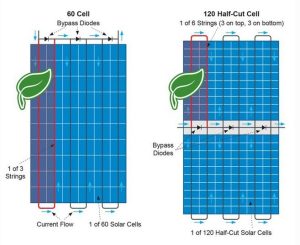

Most solar modules are made of cells that use crystalline silicon as the semiconductor material that enables electrons to be released, whenever it is exposed to light. Just like solar modules are grouped in strings in a solar system, cells are grouped in strings within a solar module (typically, three or six.)

LG Monocrystalline solar panel

Monocrystalline modules

Monocrystalline modules are made with pure silicon crystal, and offer the highest efficiency levels, as they can produce more energy per square foot than other types of modules.

These cells are typically black and appear as squares with rounded corners. This is due to the fact that the silicon ingots are shaped as cylinders, which are then cut into squares to form the ‘core’ of a cell. Whereas these modules are typically more expensive, they offer better performance when operating in high heat conditions (because of their lower temperature coefficient), as well as in indirect sunlight (i.e. cloudy weather)

Polycrystalline modules

Polycrystalline modules are made with silicon crystals, resulting in a less uniform and bluish color. Polycrystalline cells are square, slightly less efficient but are cheaper to manufacture. They are also considered to have a shorter life span than monocrystalline modules

Whereas for many years, due to their lower cost, polycrystalline modules were the most sold globally, recent advancements in monocrystalline technology have resulted in a sharp decline in polycrystalline sales.

Advancements in monocrystalline technology

Advancements in monocrystalline technology

The main reason for this major development was the arrival of Mono-Perc, Half cell and Bifacial modules.

Mono PERC (Passivated Emitter and Rear Contact): this technology allows for higher efficiency levels by adding a passivation layer in the back of the module, which reflects the light that is not absorbed by the cell, so that it can be used again to create electricity. Another advantage derived from additional light reflection is that the cell will absorb less heat (which directly impacts voltage, and therefore power output).

Half (cut) cells: this innovative way of cutting and stringing cells within the module provided another significant efficiency improvement, and is perfectly compatible with Mono-PERC technology. By cutting each cell in half, the current of each cell is halved, resulting in lower losses (loss = I² x R). At the same time, because the number of cell strings is higher than in a standard module, the impact of partial shading will be lower, as more cell string are likely not affected by shade.

The photo shows the benefits of additional cell strings, when only a portion of the module is shaded

Bifacial: these modules absorb light on the front side as well as on the rear side, which results in a higher power output (estimated at 15 to 30% extra power.) In most cases, these modules are made with Mono-PERC cells, and rather than having a white or black back sheet, will have a transparent layer, most often made of glass.

Bifacial: these modules absorb light on the front side as well as on the rear side, which results in a higher power output (estimated at 15 to 30% extra power.) In most cases, these modules are made with Mono-PERC cells, and rather than having a white or black back sheet, will have a transparent layer, most often made of glass.

In order for a sufficient amount of light to reach the back of the module, bifacial modules are usually installed on ground mounts (as in the picture shown), pergola structures (including carports), and on white flat roofs. They are particularly suitable for commercial and utility scale projects, but can also occasionally be used on residential roofs.

An important financial aspect of bifacial modules is that, in the US, bifacial modules are exempt from the Section 201 import tariffs instituted in 2018 on foreign manufactured modules. The exemption has recently been extended to 2026.

More types of Panels

Another different type of Solar panel is the Thin-film variety. The least expensive, and also the least efficient, Thin film solar panels are made from a photovoltaic substance that is applied to a substrate like glass. The TFPV (Thin Film Photovoltaic) substances used are:

- Amorphous silicon (a-Si)

- Cadmium telluride (CdTe)

- Copper indium gallium selenide (CIS/CIGS)

- Organic photovoltaic cells (OPC)

Thin film modules on a greenfield, large-scale project site

The uniform look of thin film is pleasing, and thanks to its flexibility, there are some new possibilities for harnessing solar energy. The problems with thin film solar are that it is still a relative infant in the alternative energy industry, so it is still developing. Also, its lower efficiency means it needs a great deal of space, so at this point is typically only practical in commercial or industrial settings.

What to consider when purchasing?

When considering the purchase of solar modules, these are some of the most important factors you should consider:

–Manufacturer warranty: Although a very rare instance, solar modules can occasionally underperform or show material or workmanship defects. Most manufacturers now offer both product warranty (10 to 12 years,) and a 25 to 30-year performance warranty

–Efficiency: It’s the amount of energy per module square footage, and it varies from 18 to 25%. Most likely, the highest the efficiency, the higher the price of the module. High efficiency modules can make more financial sense if the space available for the solar array is limited

–Country of Origin: the cells are not necessarily manufactured in the same country as where the modules are assembled. If you are looking for a modules manufactured in a specific country, verify the origin of the solar cells

–Size: whereas the width is always around 40”, the height can very between 69” to 84”

–Color: whereas the cells are now dark color, the back sheet can be white or black. All black modules possess a sleeker look and are preferred by many on residential installations. Bifacial modules show transparency in between the cells.

Whereas we don’t think that there is an absolute best solution that can be applied to all systems and for all locations, we certainly advise anyone interested in installing solar to consult with a local solar expert!