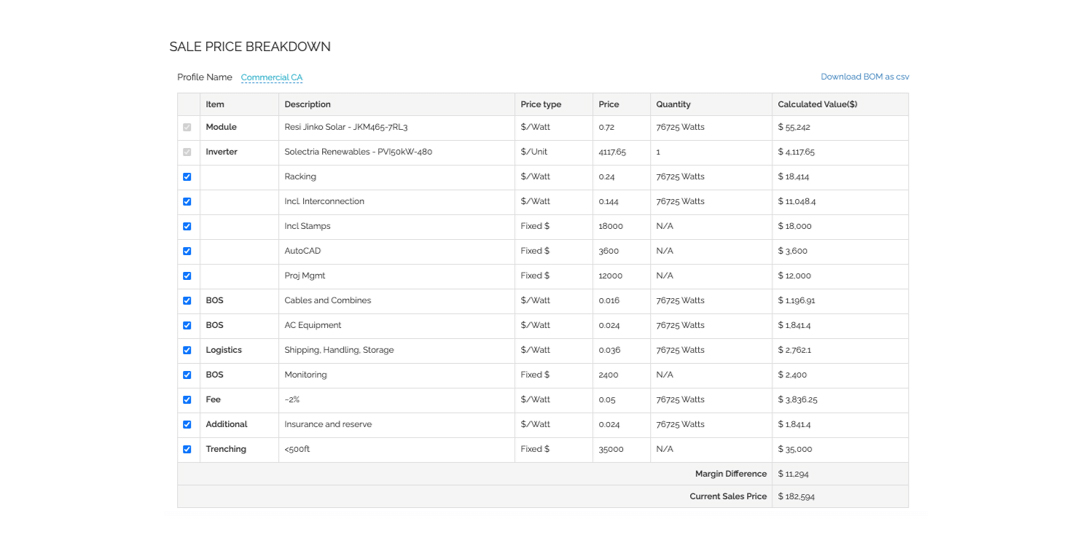

The ENACT ENVISION module for Design, Proposals and Project management of Solar and Energy storage projects has unique end-to-end capabilities, one of which is detailed cost analysisat a line-item based bill-of-materials (‘BOM’) level, that can be customized by users of any account.

Detailed Cost Modeling for Residential and Commercial Projects

ENACT allows Companies to create complex cost models for different types of projects, with unlimited number of line-item rows, and open for all units of measure, or project size. During cost-profile set-up, gross margins can be adjusted on a line-item basis. Pricing and/or cost of individual hardware items – e.g. module or inverter – can be tracked at a unit level, and vary at a model number level. Overall project margins can be tracked, adjusted to meet project goals easily and also allows ‘threshold’ limits.

Downloadable Bill-of-Material (BOM)

A new capability just launched is that the user can download an Excel-based Bill-of-material (“BOM”) for each project, that has a complete line-item level pricing and cost detail. This can help users understand the ‘margin-stack’ on a deal, which might have to be adjusted for specific deals rapidly if there is a competitive bid situation.

There are multiple Solar design software tools out there, but often have very limited capabilities on the topic of solar pricing and margin analysis. This creates a bottleneck for Operations teams, when pricing changes need to be made rapidly due to product shortages or vendor price changes.

ENACT’s ENVISION Solar proposal software provides Sales users sufficient flexibility to close a deal without bothering internal Engineering / Operations teams, that are often tied up. This enables smooth co-ordination between Sales and Operations team members as the business scales up, or during the peak season when everyone gets busy at the same time.

Detailed line-item cost tracking can also be integrated with ERP / Accounting software that allows forecasting of inventory based on order pipelines. Procurement teams can generate inventory forecasts which helps them plan orders better.